C3M

Centre for Computational Continuum Mechanics

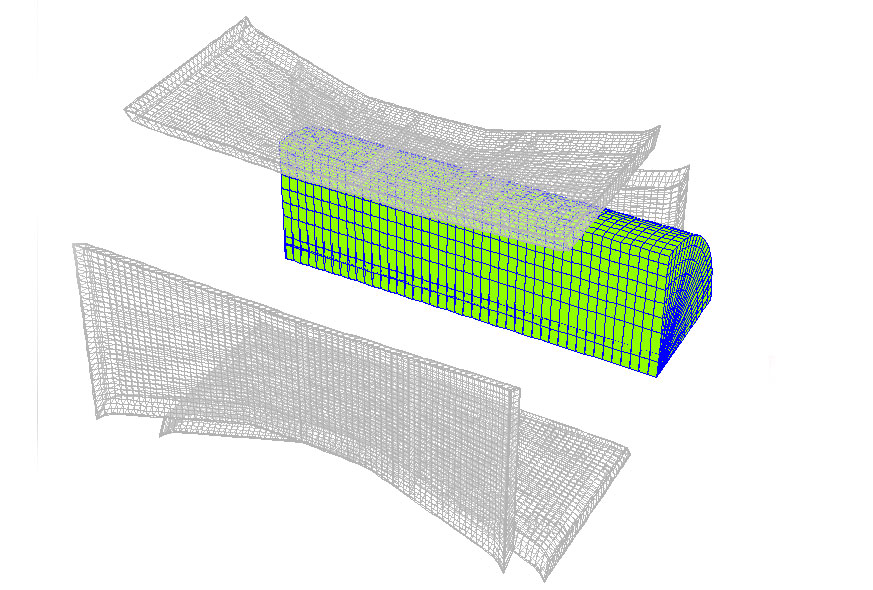

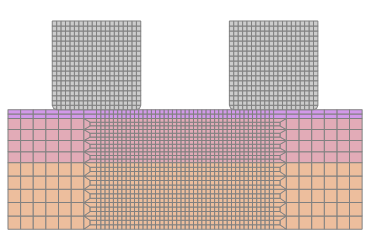

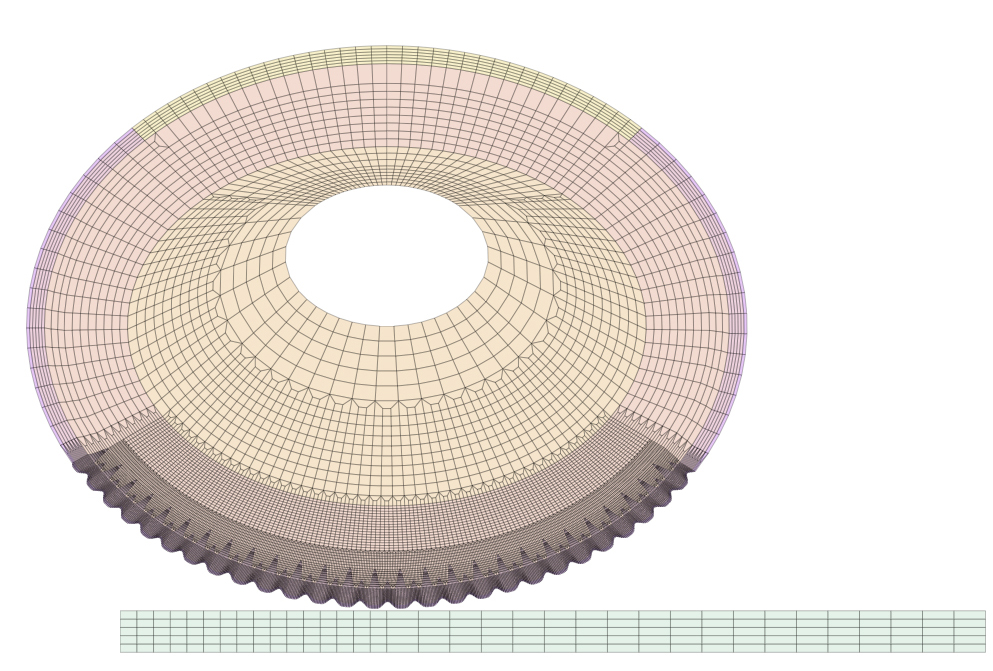

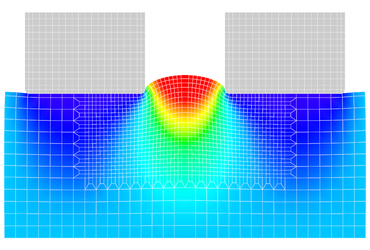

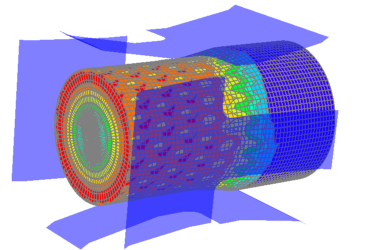

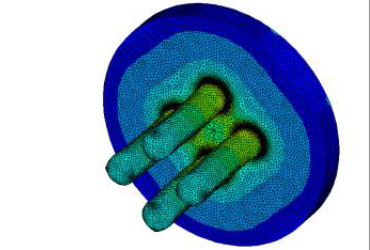

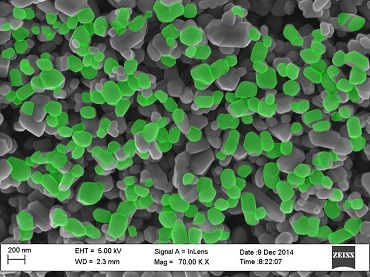

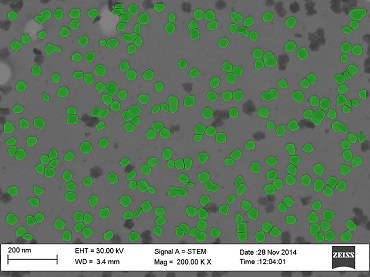

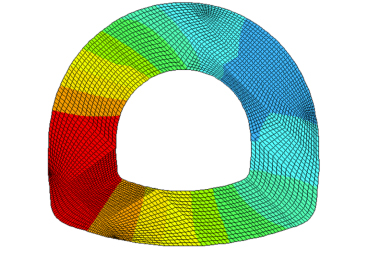

Customised numerical frameworks for direct and sensitivity analyses, inverse modelling and optimisation

C3M

Centre for Computational Continuum Mechanics

Solutions for Multi-scale, Multi-body, Multi-filed, Multi-phase and Multi-objective (M5) industrial problems