GFM FEM-Forge overview:

GFM FEM-Forge is an application for efficient 3D simulation of hot radial forging process. It can be used to enhance understanding of forging process and consequentially optimize it with respect to product quality and energy efficiency.

Main features

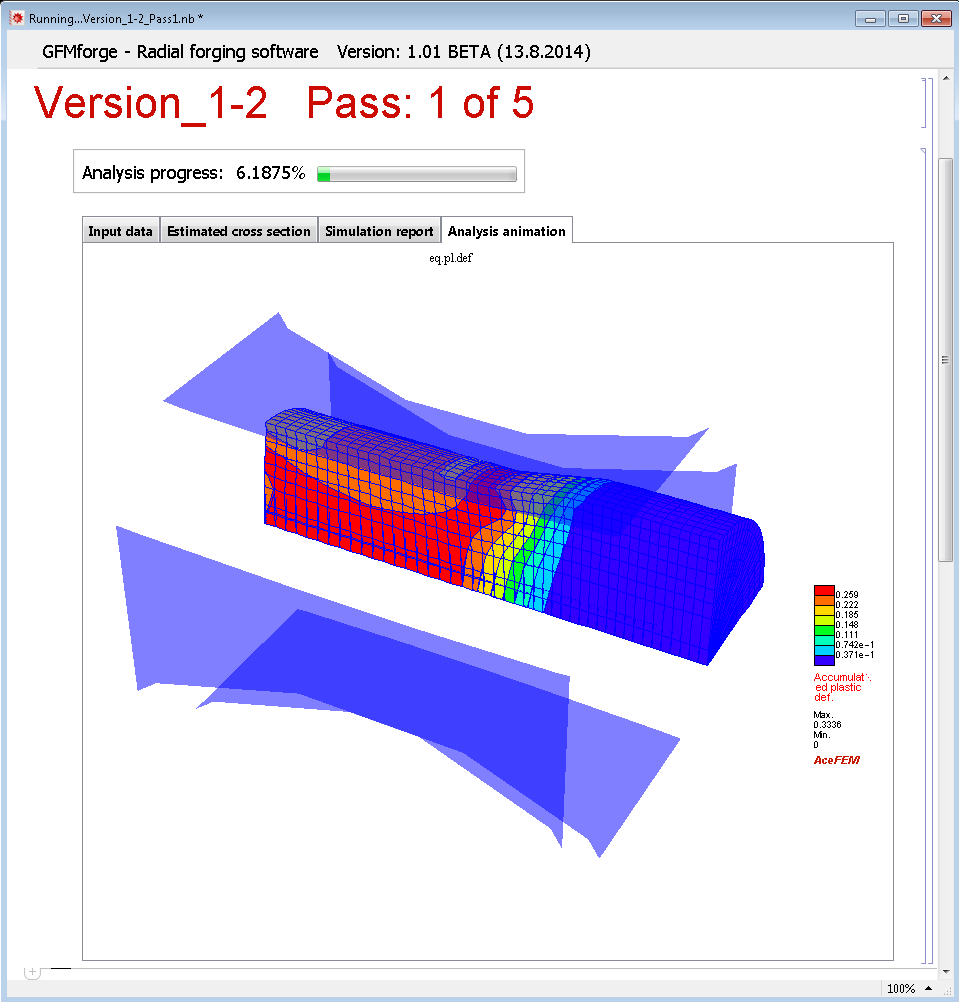

Sample of the GUI (1)

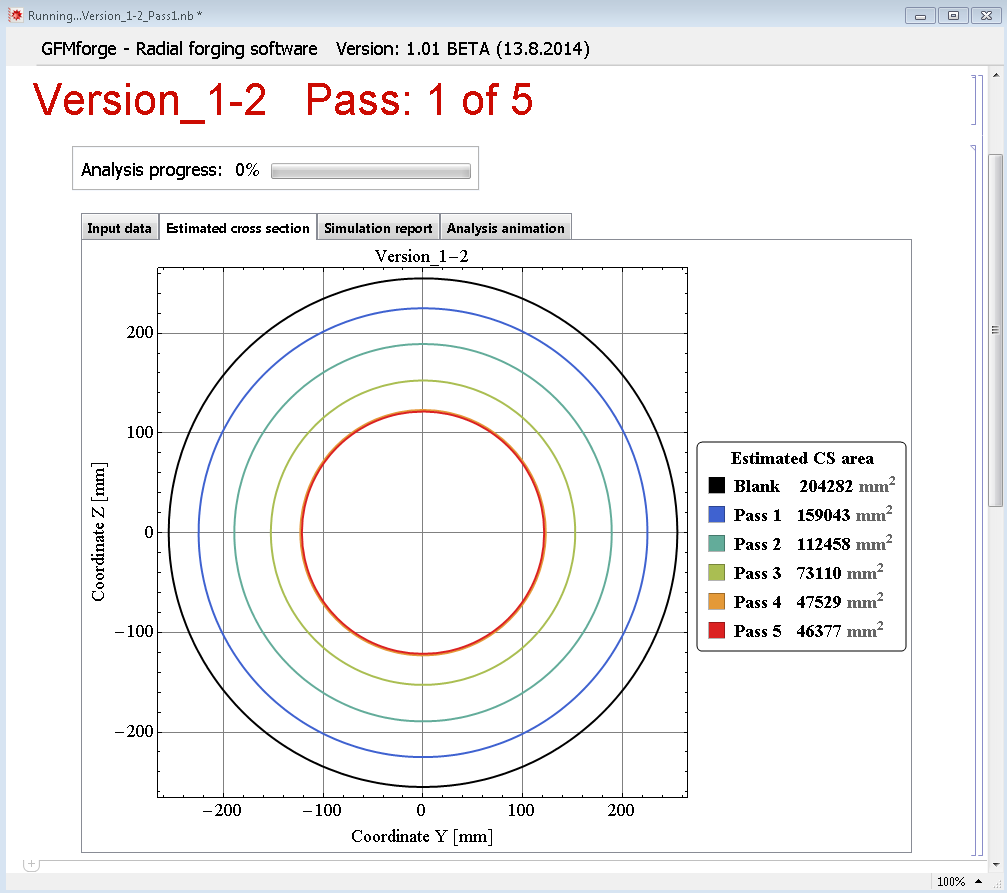

Sample of the GUI (2)

Sample of the Simulation report

Main features

- Full 3D simulations

- Realistic modelling of process kinematics

- Simulation of multiple pass forging, with changing cross-section shapes

- Import of complex hammer geometry from a CAD file

- Accurate time dependent elasto-plastic material model with thermo-mechanical coupling. Possibility to use compressive material models, suitable for powder metallurgy.

- Automatic generation of simulation reports with results

Sample of the GUI (1)

Sample of the GUI (2)

Sample of the Simulation report